Design and Analysis of a Novel 2 DOF SU-8 based Microgripper for Cell Manipulation

Description

a new design of a Microelectromechanical System based 2 degrees of freedom microgripper for cell manipulation using a polymer based material SU-8, which is known for its bio-compatibility. For high output force, V-shaped electrothermal microactuator is used and displacement amplification is achieved using a modified version of compliant parallelogram mechanism which also provides pure translational movement of micro gripping jaws with little movement in the undesired or non-gripping axis. An FEM based electro-thermo-structural analysis is performed, which predicted a gripping range of 22 µm with an applied actuation voltage of 80 mV. The maximum temperature on the microactuator is 118 ºC while on the gripping jaws, the temperature is only about 2 ºC above the room temperature.

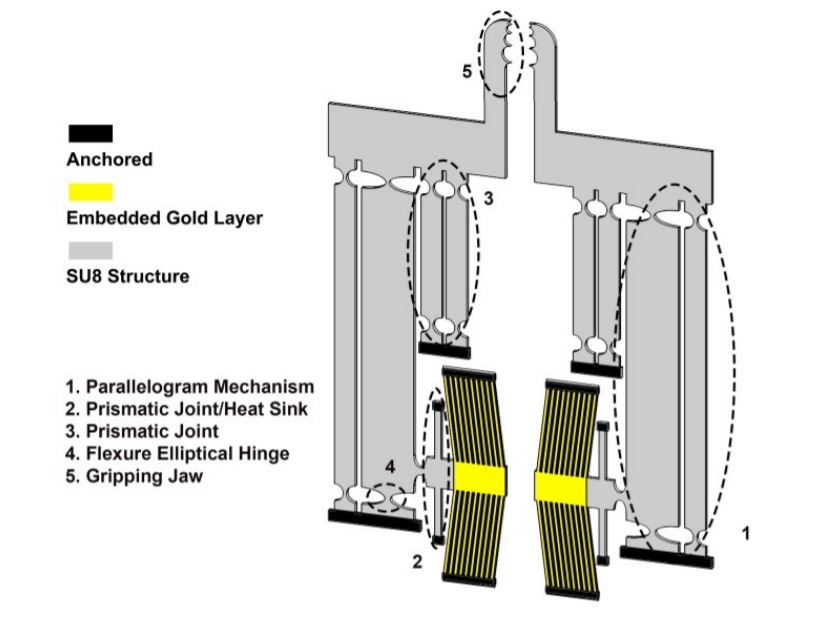

DESIGN AND WORKING OF THE PROPOSED MICROGRIPPER

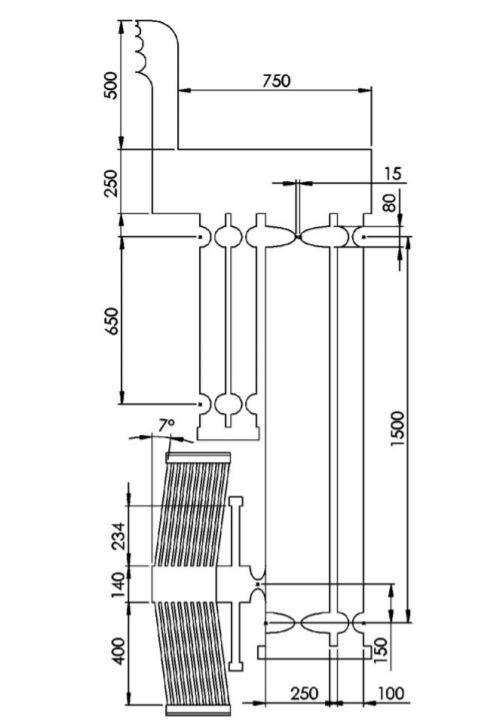

Figure 1 shows the schematic of the proposed SU-8 based electrothermally actuated microgripper with a structural layer

thickness of 20 µm. the V-shaped electrothermal microactuator is embedded with Cr/Au/Cr layers with gold layer thickness of

600 nm which acts as heater. The Cr layers are added to achieve adhesion between gold and SU-8 layers. The blackened

parts show the anchored points which are mechanically and thermally ground and the yellow parts show the plane areas on

the device where gold is embedded between two SU-8 layers.

FEM Analysis

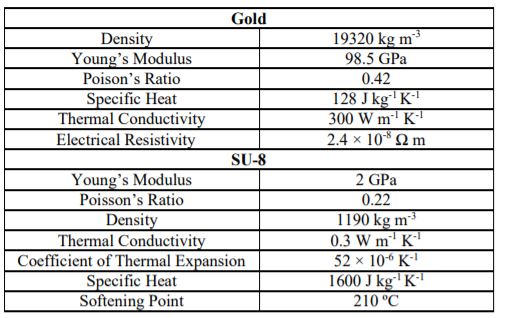

The electro-thermo-structural multi-physics numerical

analysis is performed, to analyze the performance parameters

of the proposed microgripper. The anchor points are

mechanically fixed with zero linear and rotary displacement

and thermally at room temperature (22°C). Material Properties

of SU-8 and gold used for FEM are listed in Table below.Geometric dimensions of the microgripper design are shown in figure below.

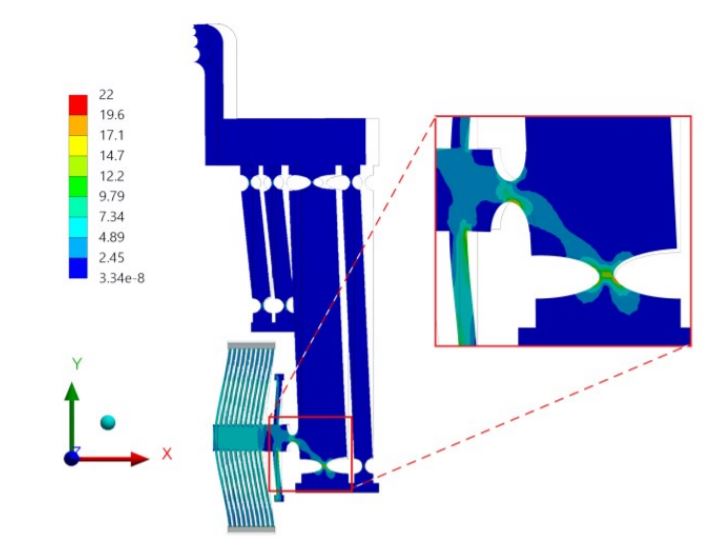

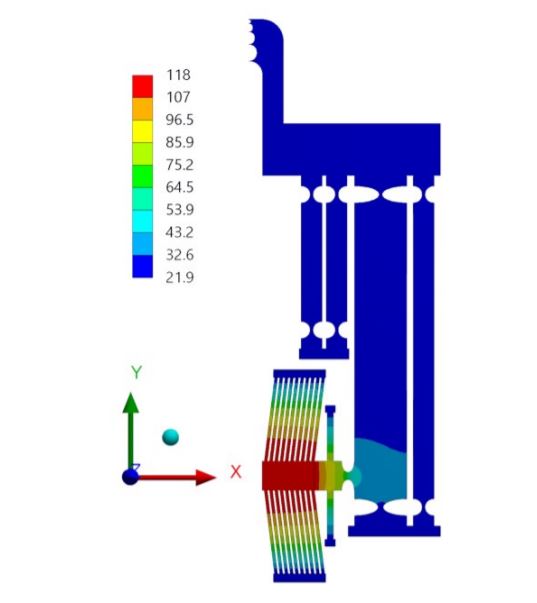

- Temperature Profile

A voltage of 80 mV is applied across the ends of the Vshaped beams of microactuator. The thermal energy produced

due to the flow of current in the embedded gold layer,thermally conducts to both the upper and lower layer of SU-8

which rises the temperature of the whole V-shaped beam of micro-actuator. The temperature gradient of the structure is

shown in Figure below.

The maximum temperature lies on the shuttle of micro actuator which is 118 °C at 80 mV which is far less than the

softening temperature of SU-8 which is 210 °C. Most importantly the tip temperature is just 2 °C above the room

temperature. The temperature profile shows it very clearly that most of the heat dissipates through the anchor points of Vshaped beams of microactuator and very less amount of heat

flows toward the compliant mechanism. It is also veryimportant to note that there is a sudden decrease in temperature

at heat sink which shows that the heat sink is working enough to prevent the heat from flowing into the compliant structure.

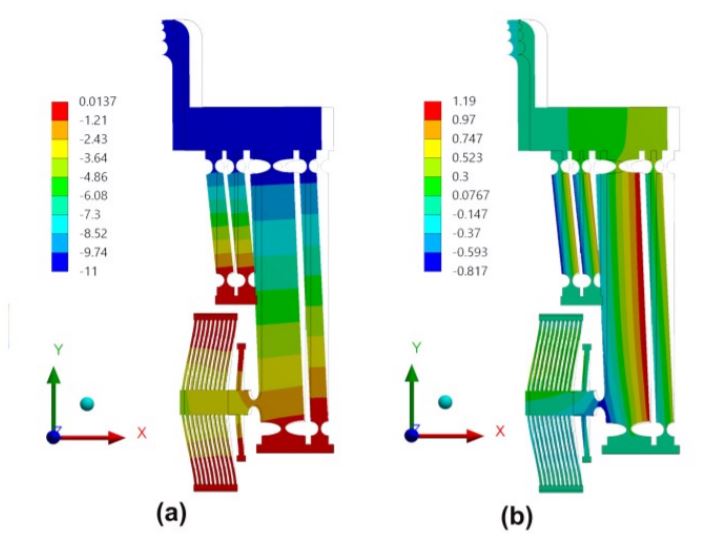

The expansion of upper and lower SU-8 layers of the Vshaped beam microactuator makes the central shuttle to move

in positive x-axis. The displacement produced at the shuttle is then amplified through the Modified Parallelogram compliant

mechanism to the gripping jaws of microgripper. The structural analysis show that the single jaw moves 11 µm in x-axis. The figure below shows that the tip displacement is purely rectilinear with minimal translation in y-axis. All pseudo rigid links are forced

in tensile so there is purely no out of plane displacement.

Since the design consists of flexure hinges which act as a

notch in the geometry, so from a designer’s perspective, stress

induced in the microstructure is very important. The value of

yield stress for SU-8, reported in literature, shows a great

variation with values ranging from 35 MPa to 80 MPa,

depending on the microfabrication process conditions and thin

film size [14]–[18]. Maximum principal stress on structure lies

on the notch which is 22 MPa at the recommended actuation

voltage of 80 mV, which is far less than the yield strength of

SU-8. This ensures safe operation of the microgripper even at

higher fatigue cycles. The FEM results are shown below.